Ask For A Quick Quote

We will contact you within 24 working hours, please pay attention to the email with the suffix “@penlucky.com”.

COME VISIT US AT OUR HQ.

Our headquarters are based in China’s Shandong District.

Stern shafts

Product Features:

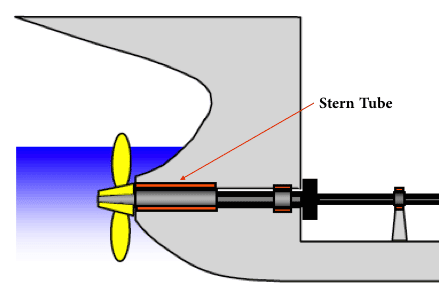

These are the housings that hold the rotating propeller shaft. On the either ends there are glands/stuffing boxes in which rubber bush bearings are fitted to hold the shaft. For wooden and fiberglass (FRP) boats we supply brass and stainless steel stern tubes and for steel boats mild steel stern tubes are supplied.

Depending on your requirements we can make the stern-tube assembly with the highest quality material. If required, we can also design these products.

Ask For A Quick Quote

We will contact you within 24 working hours, please pay attention to the email with the suffix “@penlucky.com”.

COME VISIT US AT OUR HQ.

Our headquarters are based in China’s Shandong District.

Details

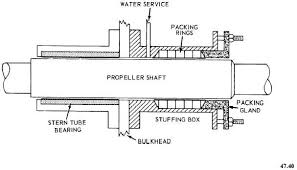

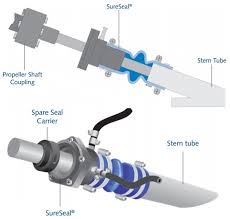

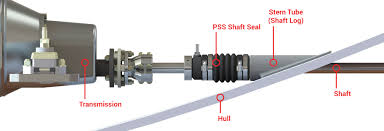

Different types of Stern Gear The stern gear is located in the rear of the hull below the water line. The propeller shaft links the propeller via the stern gear and bearings, so that the rotating motion of the engine via the gear box can be converted into thrust to propel the boat. The propeller shaft is supported by a bearing arrangement which acts as an intermediate phase between the canal water and the boat. The stern tube passes through the lower part of the hull of the vessel so carrying the shaft, and connecting it to the propeller and bearings. The lubrication arrangement and most importantly the sealing arrangements can vary in different types of narrowboat sterns. The stern tube bearing arrangement and sealing plays a vital part in the vessel’s operation. Conventional Stern Gear. These consist of a Stuffing box, central tube (also called the centre bearing) are used around the propeller shaft at the point where the boat’s hull is underwater. Rings of soft packing material are placed in the stuffing box around the shaft. When the gland nuts are tightened up on the stuffing box the packing forms a water tight seal, while allowing the propeller shaft to rotate. Various materials can be used for the packing, flax, hemp and cotton. More modern materials are now used which have graphite or Teflon in. Packing rope are often impregnated with grease or PTFE lubricants. Water lubricated This is probably the simplest of the seal designs. It consists of a rubber ring, with a lipped profile supported by a spring, contained in a housing. The rubber lip seal runs on the shaft to form the seal.This seal is generally used on: Pleasure craft. Light duty, low pressure sealing, where low cost is required.It requires little attention other than ensuring that a water supply is maintained during operation. It only requires a very small amount of special grease applying via the grease nipple every 300 hours. There is generally no back up for the seal in case of failure. there is no requirement for an additional “back-up” seal. The seal needs replacing at shorter intervals than the other seals to be safe and, prevent a “drippy” stern gear. The disadvantage is the ring gradually wears a groove in the shaft and so a replaceable liner sleeve is recommended. The rear bearing on the drive shaft which goes through the hull of a vessel, is usually made of brass with an inner grooved rubber lining that is lubricated by the surrounding water entering the grooves as it rotates. When you replace a drive shaft on your boat, it is also a good idea to replace the cutlass bearing and lip seal.